Mineralisation Extended - Multiple Intersections

Ongoing Resource Extension and Infill Drilling Results

Significant Potential for Resource Upgrades

Ewoyaa Lithium Project Ghana, West Africa

SYDNEY, AUSTRALIA / ACCESSWIRE / November 9, 2022 / Atlantic Lithium Limited (AIM:ALL)(OTCQX:ALLIF)(ASX:A11) ("Atlantic Lithium" or the "Company"), the funded African-focussed lithium exploration and development company targeting to deliver Ghana's first lithium mine, is pleased to announce assay results from the resource and exploration drilling programme which has now completed at the Ewoyaa Lithium Project ("Ewoyaa" or the "Project") in Ghana, West Africa.

Figures, Tables and Appendices referred to in this release can be viewed in the PDF version available via this link: http://www.rns-pdf.londonstockexchange.com/rns/8080F_1-2022-11-9.pdf

HIGHLIGHTS:

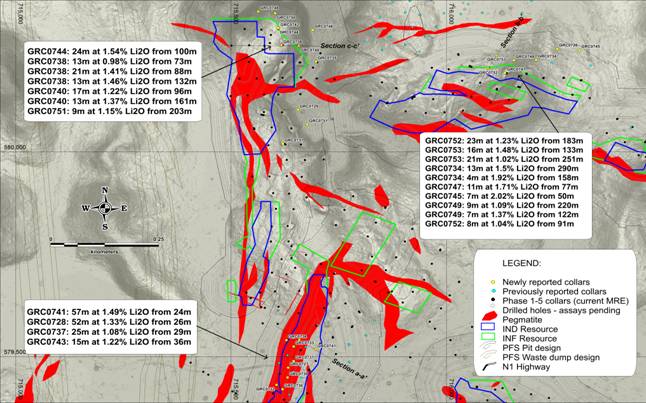

Ø Assay results reported for a further 4,709m of exploration and infill reverse circulation ("RC") drilling completed at the Grasscutter West, Ewoyaa North and Ewoyaa Main deposits, part of the now completed resource evaluation and exploration RC and diamond drilling ("DD") programme.

Ø Newly reported drilling results fall both within and outside the currently defined 30.1Mt @ 1.26% Li2O Ewoyaa JORC (2012) Compliant Mineral Resource Estimate ("MRE" or the "Resource"); extending mineralisation at the Grasscutter West and Ewoyaa North deposits and providing further confidence in Resource conversion at the Ewoyaa Main deposit.

Ø Multiple high-grade exploration drill intersections outside of the current MRE, reported at the Grasscutter West and Ewoyaa North deposits, including highlights of:

o GRC0744: 24m at 1.54% Li2O from 100m

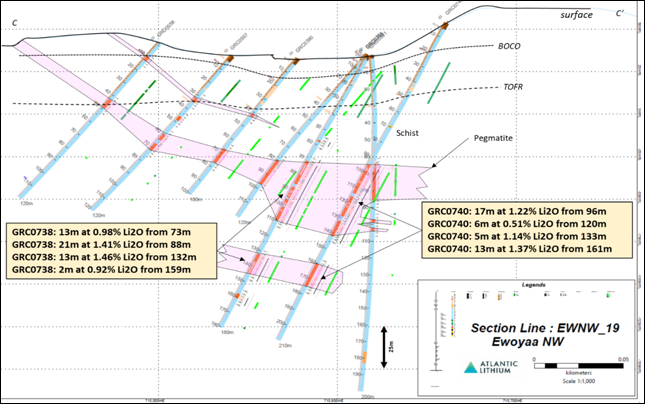

o GRC0738: 21m at 1.41% Li2O from 88m

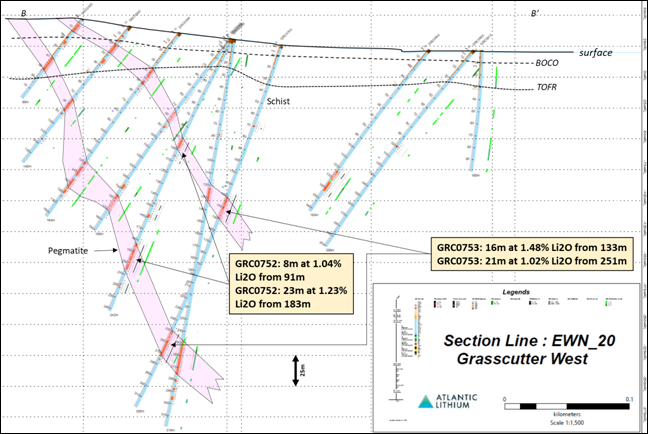

o GRC0752: 23m at 1.23% Li2O from 183m

o GRC0753: 16m at 1.48% Li2O from 133m

o GRC0753: 21m at 1.02% Li2O from 251m

o GRC0740: 17m at 1.22% Li2O from 96m

o GRC0734: 13m at 1.5% Li2O from 290m

o GRC0738: 13m at 1.46% Li2O from 132m

o GRC0747: 11m at 1.71% Li2O from 77m

o GRC0740: 13m at 1.37% Li2O from 161m

o GRC0745: 7m at 2.02% Li2O from 50m

o GRC0738: 13m at 0.98% Li2O from 73m

o GRC0751: 9m at 1.15% Li2O from 203m

o GRC0749: 9m at 1.09% Li2O from 220m

o GRC0749: 7m at 1.37% Li2O from 122m

o GRC0752: 8m at 1.04% Li2O from 91m

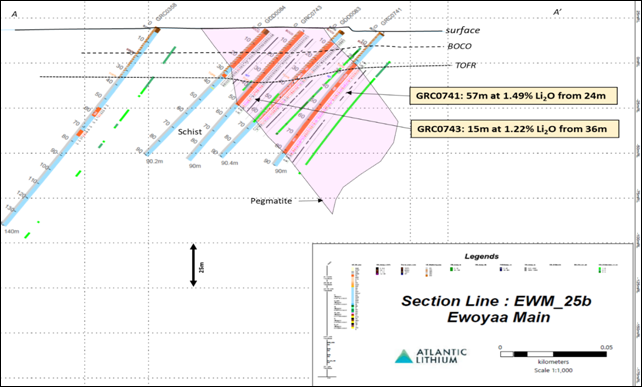

Ø Broad, high-grade exploration drill intersections within the current MRE, reported at the Ewoyaa Main deposit, including highlights of:

o GRC0741: 57m at 1.49% Li2O from 24m

o GRC0728: 52m at 1.33% Li2O from 26m

o GRC0737: 25m at 1.08% Li2O from 29m

o GRC0743: 15m at 1.22% Li2O from 36m

Ø Approximately 26,000m of results from the 47,000m drilling programme reported to date.

Ø Recently announced Pre-Feasibility Study (refer RNS of 22 September 2022) delivers exceptional financial outcomes for a 2Mtpa operation, producing an average c. 255,000tpa of 6% Li2O spodumene concentrate ("SC6") over a 12.5-year operation:

o LOM revenues exceeding US$4.84bn, Post-tax NPV8 of US$1.33bn, IRR of 224% over 12.5 years

o US$125m capital cost with an industry-leading payback period of <5 months

o C1 cash operating costs of US$278 per tonne of 6% lithium spodumene concentrate Free on Board ("FOB") Ghana Port, after by-product credits

o Average Life of Mine ("LOM") EBITDA of US$248m per annum

o 18.9Mt at 1.24% Li2O Maiden Ore Reserve

o Average annualised US$1,359/dry metric tonne SC6 pricing used

Ø Significant potential for resource upgrades and exploration upside; potential for project metrics to substantially improve with increased scale.

Commenting on the Company's latest progress, Lennard Kolff, Interim Chief Executive Officer of Atlantic Lithium, said:

"Drilling consistently delivers high-grade drill intersections, both within the infill programme targeting conversion of Indicated to Measured resources and within the exploration programme targeting resource growth outside the current MRE.

"Exploration drilling outside of the current Resource has returned multiple intersections, including highlights of 23m at 1.23% Li2O and 16m at 1.48% Li2O at the Grasscutter West deposit, and 24m at 1.54% Li2O and 21m at 1.41% Li2O at the Ewoyaa North deposit. These results demonstrate the significant growth potential at the Ewoyaa Project, with mineralisation still open along strike and downdip.

"The latest infill drilling results from within the current Resource at the Ewoyaa Main deposit have returned high-grade pegmatite intervals, including 57m at 1.49% Li2O and 52m at 1.33% Li2O, providing further confidence in future Resource to Reserve conversion.

"We anticipate further news flow from a further 21,000m of pending drilling results into the end of the year and are targeting a Resource upgrade at the end of 2022 or early 2023, dependent on lab turn-around time. The increased Resource estimate will inform a Definitive Feasibility Study, targeted for completion in mid-2023.

"With the Pre-Feasibility Study now delivered, the Mining Licence application submitted, ongoing positive drilling results and with the support of our funding agreement with Piedmont Lithium, we feel the Company is ideally positioned to benefit from the unprecedented levels of lithium demand that are expected over the coming years."

New Drilling Results:

Further assay results have been received for an additional 4,709m of RC drilling from the recently completed drill programme at the Ewoyaa Project. High-grade infill 'Measured' drill intersections are reported within the Ewoyaa Main deposit, which falls within the currently defined 30.1Mt @ 1.26% Li2O MRE (refer Table 1, Appendix 1 and Appendix 2). Additionally, multiple drill intersections are reported for exploration drilling results outside of the currently defined Resource at the Grasscutter West and Ewoyaa North deposits (refer Table 2, Appendix 1 and Appendix 2).

Table 1: High-grade infill drill intersection highlights at greater than 10 Li x m, reported at a 0.4% Li2O cut-off and a maximum of 4m of internal dilution at the Ewoyaa Main deposit.

Hole ID |

Target |

From m |

To m |

Interval m |

Hole depth m |

assay Li2O % |

Intersection |

Comment |

metal content Li x m |

GRC0741 |

MEA |

24 |

81 |

57 |

90 |

1.49 |

GRC0741: 57m at 1.49% Li2O from 24m |

84.67 |

|

GRC0728 |

MEA |

26 |

78 |

52 |

90 |

1.33 |

GRC0728: 52m at 1.33% Li2O from 26m |

69.13 |

|

GRC0737 |

MEA |

29 |

54 |

25 |

90 |

1.07 |

GRC0737: 25m at 1.08% Li2O from 29m |

26.78 |

|

GRC0743 |

MEA |

36 |

51 |

15 |

90 |

1.21 |

GRC0743: 15m at 1.22% Li2O from 36m |

18.20 |

|

GRC0739 |

MEA |

35 |

42 |

7 |

90 |

1.34 |

GRC0739: 7m at 1.35% Li2O from 35m |

9.39 |

Table 2: High-grade exploration drill intersection highlights at greater than 10 Li x m, reported at a 0.4% Li2O cut-off and maximum of 4m of internal dilution at the Grasscutter West and Ewoyaa North deposits.

Hole ID |

Target |

From m |

To m |

Interval m |

Hole depth m |

assay Li2O % |

Intersection |

Comment |

metal content Li x m |

GRC0744 |

EXPL |

100 |

124 |

24 |

164 |

1.53 |

GRC0744: 24m at 1.54% Li2O from 100m |

36.83 |

|

GRC0738 |

EXPL |

88 |

109 |

21 |

180 |

1.41 |

GRC0738: 21m at 1.41% Li2O from 88m |

29.55 |

|

GRC0752 |

EXPL |

183 |

206 |

23 |

242 |

1.23 |

GRC0752: 23m at 1.23% Li2O from 183m |

28.22 |

|

GRC0753 |

EXPL |

133 |

149 |

16 |

320 |

1.47 |

GRC0753: 16m at 1.48% Li2O from 133m |

23.57 |

|

GRC0753 |

EXPL |

251 |

272 |

21 |

320 |

1.02 |

GRC0753: 21m at 1.02% Li2O from 251m |

21.42 |

|

GRC0740 |

EXPL |

96 |

113 |

17 |

210 |

1.21 |

GRC0740: 17m at 1.22% Li2O from 96m |

20.64 |

|

GRC0734 |

EXPL |

290 |

303 |

13 |

333 |

1.49 |

GRC0734: 13m at 1.5% Li2O from 290m |

19.40 |

|

GRC0738 |

EXPL |

132 |

145 |

13 |

180 |

1.45 |

GRC0738: 13m at 1.46% Li2O from 132m |

18.91 |

|

GRC0747 |

EXPL |

77 |

88 |

11 |

252 |

1.70 |

GRC0747: 11m at 1.71% Li2O from 77m |

18.73 |

|

GRC0740 |

EXPL |

161 |

174 |

13 |

210 |

1.36 |

GRC0740: 13m at 1.37% Li2O from 161m |

17.71 |

|

GRC0745 |

EXPL |

50 |

57 |

7 |

320 |

2.01 |

GRC0745: 7m at 2.02% Li2O from 50m |

14.10 |

|

GRC0738 |

EXPL |

73 |

86 |

13 |

180 |

0.98 |

GRC0738: 13m at 0.98% Li2O from 73m |

12.70 |

|

GRC0751 |

EXPL |

203 |

212 |

9 |

260 |

1.14 |

GRC0751: 9m at 1.15% Li2O from 203m |

10.29 |

|

GRC0749 |

EXPL |

220 |

229 |

9 |

294 |

1.08 |

GRC0749: 9m at 1.09% Li2O from 220m |

9.74 |

|

GRC0749 |

EXPL |

122 |

129 |

7 |

294 |

1.37 |

GRC0749: 7m at 1.37% Li2O from 122m |

9.58 |

Resource infill drilling results received to date at the Ewoyaa Main deposit have confirmed good mineralisation continuity from the surface and increased resource confidence on a nominal 20m x 20m grid. Measured drilling targeted the first 1.5 to 2 years of planned production at the Ewoyaa Main deposit. Additionally, infill drilling provided further material for test work and customer acceptance samples within the planned starter pit.

High grades were reported within the proposed starter pit zone of the Ewoyaa Main deposit, including highlights of 57m at 1.49% Li2O from 24m and 52m at 1.33% Li2O from 26m (refer Figure 1 and Figure 2).

Exploration drilling results outside the 30.1Mt at 1.26% Li2O Resource continue to demonstrate further resource scale potential at the Ewoyaa Project, where multiple new drilling intersections have confirmed mineralisation extensions along strike and down dip at the Grasscutter West and Ewoyaa North deposits (refer Figure 1, Figure 3 and Figure 4).

Sample preparation was completed by Intertek Ghana and assay by Intertek Perth with all reported results passing QA/QC protocols, providing confidence in reported results.

Figure 1: Location of reported assay results with highlight drill intersections for Measured holes and Exploration holes.

Figure 2: Cross-section A-A' showing assay results received for infill holes GRC0741 and GRC0743 at the Ewoyaa Main deposit.

Figure 3: Cross-section C-C' assay results received for exploration holes GRC0738 and GRC0740 at the Ewoyaa North deposit.

Figure 4: Cross-section B-B' assay results received for exploration holes GRC0752 and GRC0753 at the Grasscutter West deposit.

Competent Persons

Information in this report relating to the exploration results is based on data reviewed by Mr Lennard Kolff (MEcon. Geol., BSc. Hons ARSM), Chief Geologist of the Company. Mr Kolff is a Member of the Australian Institute of Geoscientists who has in excess of 20 years' experience in mineral exploration and is a Qualified Person under the AIM Rules. Mr Kolff consents to the inclusion of the information in the form and context in which it appears.

Information in this report relating to Mineral Resources was compiled by Shaun Searle, a Member of the Australian Institute of Geoscientists. Mr Searle has sufficient experience that is relevant to the style of mineralisation and type of deposit under consideration and to the activity being undertaken to qualify as a Competent Person as defined in the 2012 Edition of the 'Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves'. Mr Searle is a director of Ashmore. Ashmore and the Competent Person are independent of the Company and other than being paid fees for services in compiling this report, neither has any financial interest (direct or contingent) in the Company. Mr Searle consents to the inclusion in the report of the matters based upon the information in the form and context in which it appears.

The reported Ore Reserves have been compiled by Mr Harry Warries. Mr Warries is a Fellow of the Australasian Institute of Mining and Metallurgy and an employee of Mining Focus Consultants Pty Ltd. He has sufficient experience, relevant to the style of mineralisation and type of deposit under consideration and to the activity he is undertaking, to qualify as a Competent Person as defined in the 'Australasian Code for Reporting of Mineral Resources and Ore Reserves' of December 2012 ("JORC Code") as prepared by the Joint Ore Reserves Committee of the Australasian Institute of Mining and Metallurgy, the Australian Institute of Geoscientists and the Minerals Council of Australia. Mr Warries gives Atlantic Lithium Limited consent to use this reserve estimate in reports.

This announcement contains inside information for the purposes of Article 7 of the Market Abuse Regulation (EU) 596/2014 as it forms part of UK domestic law by virtue of the European Union (Withdrawal) Act 2018 ("MAR"), and is disclosed in accordance with the Company's obligations under Article 17 of MAR.

For any further information, please contact:

|

Atlantic Lithium Limited Lennard Kolff (Interim CEO) Amanda Harsas (Finance Director and Company Secretary) |

Tel: +61 2 8072 0640 |

|

SP Angel Corporate Finance LLP Nominated Adviser Jeff Keating Charlie Bouverat |

Tel: +44 (0)20 3470 0470 |

|

Canaccord Genuity Limited Joint Company Broker Raj Khatri James Asensio Harry Rees |

Tel: +44 (0) 20 7523 4500 |

|

Liberum Capital Limited Joint Company Broker Scott Mathieson Edward Thomas Kane Collings |

Tel: +44 (0) 20 3100 2000 |

|

Yellow Jersey PR Limited Henry Wilkinson Dominic Barretto James Lingfield |

Tel: +44 (0)20 3004 9512 |

Notes to Editors:

About Atlantic Lithium

Atlantic Lithium is an AIM and ASX-listed lithium company advancing a portfolio of lithium projects in Ghana and Côte d'Ivoire through to production.

The Company's flagship project, the Ewoyaa Project in Ghana, is a significant lithium spodumene pegmatite discovery on track to become Ghana's first lithium-producing mine. The Company signed a funding agreement with Piedmont Lithium Inc. for US$103m towards the development of the Ewoyaa Project. Based on the Pre-Feasibility Study, the Ewoyaa Project has indicated Life of Mine revenues exceeding US$4.84bn, producing a spodumene concentrate via simple gravity only process flowsheet.

Atlantic Lithium holds 560km2 & 774km2 of tenure across Ghana and Côte d'Ivoire respectively, comprising significantly under-explored, highly prospective licenses.

Appendix 1 - New drill intersections reported in hole ID order, reported at a 0.4% Li2O cut-off and maximum 4m of internal dilution.

Hole ID |

Hole target |

From m |

To m |

Interval m |

Hole depth m |

Assay Li2O % |

Intersection |

Comment |

metal content Li x m |

GRC0727 |

MEA |

2 |

4 |

2 |

90 |

0.82 |

GRC0727: 2m at 0.83% Li2O from 2m |

weathered pegmatite |

1.65 |

GRC0727 |

MEA |

23 |

28 |

5 |

90 |

0.64 |

GRC0727: 5m at 0.65% Li2O from 23m |

weathered pegmatite |

3.20 |

GRC0728 |

MEA |

26 |

78 |

52 |

90 |

1.33 |

GRC0728: 52m at 1.33% Li2O from 26m |

69.13 |

|

GRC0728 |

MEA |

80 |

82 |

2 |

90 |

0.79 |

GRC0728: 2m at 0.8% Li2O from 80m |

1.58 |

|

GRC0729 |

EXPL |

104 |

106 |

2 |

226 |

0.53 |

GRC0729: 2m at 0.54% Li2O from 104m |

1.06 |

|

GRC0729 |

EXPL |

174 |

176 |

2 |

226 |

0.63 |

GRC0729: 2m at 0.63% Li2O from 174m |

1.25 |

|

GRC0729 |

EXPL |

178 |

188 |

10 |

226 |

0.51 |

GRC0729: 10m at 0.52% Li2O from 178m |

5.12 |

|

GRC0729 |

EXPL |

193 |

194 |

1 |

226 |

0.51 |

GRC0729: 1m at 0.52% Li2O from 193m |

0.51 |

|

GRC0730 |

MEA |

28 |

37 |

9 |

90 |

0.89 |

GRC0730: 9m at 0.9% Li2O from 28m |

weathered pegmatite |

8.04 |

GRC0730 |

MEA |

42 |

43 |

1 |

90 |

0.96 |

GRC0730: 1m at 0.96% Li2O from 42m |

0.96 |

|

GRC0731 |

EXPL |

33 |

34 |

1 |

200 |

0.60 |

GRC0731: 1m at 0.6% Li2O from 33m |

0.60 |

|

GRC0731 |

EXPL |

168 |

173 |

5 |

200 |

1.01 |

GRC0731: 5m at 1.01% Li2O from 168m |

5.05 |

|

GRC0732 |

MEA |

2 |

21 |

19 |

50 |

no significant intersections |

weathered pegmatite |

||

GRC0732 |

MEA |

28 |

29 |

1 |

50 |

no significant intersections |

weathered pegmatite |

||

GRC0732 |

MEA |

40 |

41 |

1 |

50 |

no significant intersections |

|||

GRC0733 |

MEA |

13 |

14 |

1 |

90 |

0.72 |

GRC0733: 1m at 0.72% Li2O from 13m |

weathered pegmatite |

0.72 |

GRC0733 |

MEA |

26 |

27 |

1 |

90 |

0.55 |

GRC0733: 1m at 0.56% Li2O from 26m |

weathered pegmatite |

0.55 |

GRC0733 |

MEA |

35 |

39 |

4 |

90 |

0.59 |

GRC0733: 4m at 0.59% Li2O from 35m |

weathered pegmatite |

2.35 |

GRC0734 |

EXPL |

158 |

162 |

4 |

333 |

1.91 |

GRC0734: 4m at 1.92% Li2O from 158m |

7.65 |

|

GRC0734 |

EXPL |

185 |

191 |

6 |

333 |

1.15 |

GRC0734: 6m at 1.15% Li2O from 185m |

6.88 |

|

GRC0734 |

EXPL |

271 |

274 |

3 |

333 |

0.81 |

GRC0734: 3m at 0.81% Li2O from 271m |

2.42 |

|

GRC0734 |

EXPL |

290 |

303 |

13 |

333 |

1.49 |

GRC0734: 13m at 1.5% Li2O from 290m |

19.40 |

|

GRC0735 |

EXPL |

128 |

132 |

4 |

180 |

0.75 |

GRC0735: 4m at 0.76% Li2O from 128m |

3.00 |

|

GRC0736 |

MEA |

10 |

11 |

1 |

90 |

0.46 |

GRC0736: 1m at 0.47% Li2O from 10m |

weathered pegmatite |

0.46 |

GRC0737 |

MEA |

1 |

4 |

3 |

90 |

1.49 |

GRC0737: 3m at 1.5% Li2O from 1m |

weathered pegmatite |

4.47 |

GRC0737 |

MEA |

11 |

12 |

1 |

90 |

0.40 |

GRC0737: 1m at 0.41% Li2O from 11m |

weathered pegmatite |

0.40 |

GRC0737 |

MEA |

18 |

22 |

5 |

90 |

0.57 |

GRC0737: 5m at 0.57% Li2O from 18m |

weathered pegmatite |

2.85 |

GRC0737 |

MEA |

29 |

54 |

25 |

90 |

1.07 |

GRC0737: 25m at 1.08% Li2O from 29m |

26.78 |

|

GRC0738 |

EXPL |

73 |

86 |

13 |

180 |

0.98 |

GRC0738: 13m at 0.98% Li2O from 73m |

12.70 |

|

GRC0738 |

EXPL |

88 |

109 |

21 |

180 |

1.41 |

GRC0738: 21m at 1.41% Li2O from 88m |

29.55 |

|

GRC0738 |

EXPL |

132 |

145 |

13 |

180 |

1.45 |

GRC0738: 13m at 1.46% Li2O from 132m |

18.91 |

|

GRC0738 |

EXPL |

159 |

161 |

2 |

180 |

0.91 |

GRC0738: 2m at 0.92% Li2O from 159m |

1.83 |

|

GRC0739 |

MEA |

35 |

42 |

7 |

90 |

1.34 |

GRC0739: 7m at 1.35% Li2O from 35m |

9.39 |

|

GRC0740 |

EXPL |

96 |

113 |

17 |

210 |

1.21 |

GRC0740: 17m at 1.22% Li2O from 96m |

20.64 |

|

GRC0740 |

EXPL |

120 |

126 |

6 |

210 |

0.50 |

GRC0740: 6m at 0.51% Li2O from 120m |

3.01 |

|

GRC0740 |

EXPL |

133 |

138 |

5 |

210 |

1.14 |

GRC0740: 5m at 1.14% Li2O from 133m |

5.70 |

|

GRC0740 |

EXPL |

161 |

174 |

13 |

210 |

1.36 |

GRC0740: 13m at 1.37% Li2O from 161m |

17.71 |

|

GRC0741 |

MEA |

24 |

81 |

57 |

90 |

1.49 |

GRC0741: 57m at 1.49% Li2O from 24m |

84.67 |

|

GRC0742 |

EXPL |

94 |

99 |

5 |

200 |

0.98 |

GRC0742: 5m at 0.98% Li2O from 94m |

4.89 |

|

GRC0742 |

EXPL |

161 |

165 |

4 |

200 |

1.24 |

GRC0742: 4m at 1.24% Li2O from 161m |

4.95 |

|

GRC0743 |

MEA |

36 |

51 |

15 |

90 |

1.21 |

GRC0743: 15m at 1.22% Li2O from 36m |

18.20 |

|

GRC0744 |

EXPL |

100 |

124 |

24 |

164 |

1.53 |

GRC0744: 24m at 1.54% Li2O from 100m |

36.83 |

|

GRC0745 |

EXPL |

50 |

57 |

7 |

320 |

2.01 |

GRC0745: 7m at 2.02% Li2O from 50m |

14.10 |

|

GRC0745 |

EXPL |

102 |

103 |

1 |

320 |

0.43 |

GRC0745: 1m at 0.44% Li2O from 102m |

0.43 |

|

GRC0745 |

EXPL |

290 |

291 |

1 |

320 |

0.41 |

GRC0745: 1m at 0.41% Li2O from 290m |

0.41 |

|

GRC0746 |

EXPL |

142 |

148 |

6 |

188 |

1.23 |

GRC0746: 6m at 1.24% Li2O from 142m |

7.41 |

|

GRC0747 |

EXPL |

77 |

88 |

11 |

252 |

1.70 |

GRC0747: 11m at 1.71% Li2O from 77m |

18.73 |

|

GRC0747 |

EXPL |

106 |

109 |

3 |

252 |

1.36 |

GRC0747: 3m at 1.37% Li2O from 106m |

4.08 |

|

GRC0747 |

EXPL |

137 |

141 |

4 |

252 |

0.45 |

GRC0747: 4m at 0.46% Li2O from 137m |

1.80 |

|

GRC0747 |

EXPL |

193 |

197 |

4 |

252 |

1.43 |

GRC0747: 4m at 1.43% Li2O from 193m |

5.71 |

|

GRC0747 |

EXPL |

199 |

203 |

4 |

252 |

1.35 |

GRC0747: 4m at 1.36% Li2O from 199m |

5.41 |

|

GRC0748 |

EXPL |

83 |

86 |

3 |

120 |

1.11 |

GRC0748: 3m at 1.12% Li2O from 83m |

3.33 |

|

GRC0749 |

EXPL |

122 |

129 |

7 |

294 |

1.37 |

GRC0749: 7m at 1.37% Li2O from 122m |

9.58 |

|

GRC0749 |

EXPL |

142 |

147 |

5 |

294 |

1.42 |

GRC0749: 5m at 1.42% Li2O from 142m |

7.10 |

|

GRC0749 |

EXPL |

220 |

229 |

9 |

294 |

1.08 |

GRC0749: 9m at 1.09% Li2O from 220m |

9.74 |

|

GRC0749 |

EXPL |

234 |

235 |

1 |

294 |

0.95 |

GRC0749: 1m at 0.95% Li2O from 234m |

0.95 |

|

GRC0750 |

EXPL |

127 |

131 |

4 |

160 |

1.00 |

GRC0750: 4m at 1.01% Li2O from 127m |

4.01 |

|

GRC0750 |

EXPL |

149 |

150 |

1 |

160 |

0.78 |

GRC0750: 1m at 0.78% Li2O from 149m |

0.78 |

|

GRC0751 |

EXPL |

203 |

212 |

9 |

260 |

1.14 |

GRC0751: 9m at 1.15% Li2O from 203m |

10.29 |

|

GRC0752 |

EXPL |

91 |

99 |

8 |

242 |

1.03 |

GRC0752: 8m at 1.04% Li2O from 91m |

8.25 |

|

GRC0752 |

EXPL |

183 |

206 |

23 |

242 |

1.23 |

GRC0752: 23m at 1.23% Li2O from 183m |

28.22 |

|

GRC0753 |

EXPL |

133 |

149 |

16 |

320 |

1.47 |

GRC0753: 16m at 1.48% Li2O from 133m |

23.57 |

|

GRC0753 |

EXPL |

251 |

272 |

21 |

320 |

1.02 |

GRC0753: 21m at 1.02% Li2O from 251m |

21.42 |

|

GRC0754 |

EXPL |

26 |

29 |

3 |

100 |

no significant intersections |

|||

GRC0754 |

EXPL |

66 |

67 |

1 |

100 |

no significant intersections |

Appendix 2 - Newly reported drill collar locations (MEA = Measured, IND = Indicated, EXPL = Exploration)

Hole_ID |

hole target |

Hole depth m |

Eastings |

Northings |

Elevation m |

Dip |

Hole Azimuth |

GRC0727 |

MEA |

90.00 |

715632 |

579473 |

17.29 |

-50 |

305 |

GRC0728 |

MEA |

90.00 |

715677 |

579500 |

17.00 |

-50 |

305 |

GRC0729 |

EXPL |

226.00 |

715655 |

580103 |

61.63 |

-50 |

270 |

GRC0730 |

MEA |

90.00 |

715619 |

579420 |

16.81 |

-50 |

305 |

GRC0731 |

EXPL |

200.00 |

715620 |

580020 |

40.23 |

-60 |

270 |

GRC0732 |

MEA |

50.00 |

715605 |

579431 |

16.97 |

-50 |

305 |

GRC0733 |

MEA |

90.00 |

715645 |

579525 |

17.50 |

-50 |

305 |

GRC0734 |

EXPL |

333.00 |

716208 |

580225 |

40.40 |

-70 |

210 |

GRC0735 |

EXPL |

180.00 |

715697 |

580221 |

63.36 |

-60 |

270 |

GRC0736 |

MEA |

90.00 |

715628 |

579540 |

17.78 |

-50 |

305 |

GRC0737 |

MEA |

90.00 |

715645 |

579489 |

17.37 |

-50 |

305 |

GRC0738 |

EXPL |

180.00 |

715617 |

580260 |

34.52 |

-60 |

270 |

GRC0739 |

MEA |

90.00 |

715631 |

579449 |

17.08 |

-50 |

305 |

GRC0740 |

EXPL |

210.00 |

715657 |

580259 |

50.56 |

-60 |

270 |

GRC0741 |

MEA |

90.00 |

715696 |

579517 |

17.38 |

-50 |

305 |

GRC0742 |

EXPL |

200.00 |

715610 |

580302 |

35.98 |

-65 |

270 |

GRC0743 |

MEA |

90.00 |

715658 |

579541 |

18.79 |

-50 |

305 |

GRC0744 |

EXPL |

164.00 |

715609 |

580303 |

36.20 |

-90 |

0 |

GRC0745 |

EXPL |

320.00 |

716309 |

580249 |

26.85 |

-70 |

210 |

GRC0746 |

EXPL |

188.00 |

715689 |

580298 |

65.23 |

-80 |

270 |

GRC0747 |

EXPL |

252.00 |

716136 |

580193 |

38.99 |

-60 |

210 |

GRC0748 |

EXPL |

120.00 |

715563 |

580343 |

54.06 |

-50 |

270 |

GRC0749 |

EXPL |

294.00 |

716156 |

580224 |

33.60 |

-60 |

210 |

GRC0750 |

EXPL |

160.00 |

715602 |

580339 |

47.02 |

-50 |

270 |

GRC0751 |

EXPL |

260.00 |

715677 |

580067 |

60.39 |

-50 |

270 |

GRC0752 |

EXPL |

242.00 |

716097 |

580204 |

30.42 |

-60 |

210 |

GRC0753 |

EXPL |

320.00 |

716116 |

580236 |

43.00 |

-70 |

210 |

GRC0754 |

EXPL |

100.00 |

714213 |

577533 |

48.00 |

-90 |

0 |

'JORC Code 2012 Table 1' Section 1 Sampling Techniques and Data

The following extract from the JORC Code 2012 Table 1 is provided for compliance with the Code requirements for the reporting of Exploration Results.

Sampling techniques |

· Nature and quality of sampling (eg cut channels, random chips, or specific specialised industry standard measurement tools appropriate to the minerals under investigation, such as down hole gamma sondes, or handheld XRF instruments, etc). These examples should not be taken as limiting the broad meaning of sampling. · Include reference to measures taken to ensure sample representivity and the appropriate calibration of any measurement tools or systems used. · Aspects of the determination of mineralisation that are Material to the Public Report. In cases where 'industry standard' work has been done this would be relatively simple (eg 'reverse circulation drilling was used to obtain 1 m samples from which 3 kg was pulverised to produce a 30 g charge for fire assay'). In other cases, more explanation may be required, such as where there is coarse gold that has inherent sampling problems. Unusual commodities or mineralisation types (eg submarine nodules) may warrant disclosure of detailed information. |

· RC drill holes were routinely sampled at 1m intervals with a nominal 3-6kg sub-sample split off for assay using a rig-mounted cone splitter at 1m intervals. · DD holes were quarter core sampled at 1m intervals or to geological contacts for geochemical analysis. · For assaying, splits from all prospective ore zones (i.e., logged pegmatites +/- interburden) were sent for assay. Outside of these zones, the splits were composited to 4m using a portable riffle splitter. · Holes without pegmatite were not assayed. · Approximately 5% of all samples submitted were standards and coarse blanks. Blanks were typically inserted with the interpreted ore zones after the drilling was completed. · Approximately 2.5% of samples submitted were duplicate samples collected after logging using a riffle splitter and sent to an umpire laboratory. This ensured zones of interest were duplicated and not missed during alternative routine splitting of the primary sample. · Prior to the December 2018 - SGS Tarkwa was used for sample preparation (PRP100) and subsequently forwarded to SGS Johannesburg for analysis; and later SGS Vancouver for analysis (ICP90A). · Post December 2018 to present - Intertek Tarkwa was used for sample preparation (SP02/SP12) and subsequently forwarded to Intertek Perth for analysis (FP6/MS/OES - 21 element combination Na2O2 fusion with combination OES/MS). · ALS Laboratory in Brisbane was used for the Company's initial due diligence work programmes and was selected as the umpire laboratory since Phase 1. ALS conducts ME-ICP89, with a Sodium Peroxide Fusion. Detection limits for lithium are 0.01-10%. Sodium Peroxide fusion is considered a "total" assay technique for lithium. In addition, 22 additional elements assayed with Na2O2 fusion, and combination MS/ICP analysis. |

Drilling techniques |

· Drill type (eg core, reverse circulation, open-hole hammer, rotary air blast, auger, Bangka, sonic, etc) and details (eg core diameter, triple or standard tube, depth of diamond tails, face-sampling bit or other type, whether core is oriented and if so, by what method, etc). |

· Five phases of drilling were undertaken at the Project using RC and DD techniques. All the RC drilling used face sampling hammers. · Phase 1 and 2 programmes used a 5.25-inch hammers while Phase 3 and 5 used a 5.75-inch hammer. · All DD holes were completed using PQ and HQ core from surface (85mm and 63.5mm). · All DD holes were drilled in conjunction with a Reflex ACT II tool; to provide an accurate determination of the bottom-of-hole orientation. · All fresh core was orientated to allow for geological, structural and geotechnical logging by a Company geologist. |

Drill sample recovery |

· Method of recording and assessing core and chip sample recoveries and results assessed. · Measures taken to maximise sample recovery and ensure representative nature of the samples. · Whether a relationship exists between sample recovery and grade and whether sample bias may have occurred due to preferential loss/gain of fine/coarse material. |

· A semi-quantitative estimate of sample recovery was completed for the vast majority of drilling. This involved weighing both the bulk samples and splits and calculating theoretical recoveries using assumed densities. Where samples were not weighed, qualitative descriptions of the sample size were recorded. Some sample loss was recorded in the collaring of the RC drill holes. · DD recoveries were measured and recorded. Recoveries in excess of 95.8% have been achieved for the DD drilling programme. Drill sample recovery and quality is adequate for the drilling technique employed. · The DD twin programme has identified a positive grade bias for iron in the RC compared to the DD results. |

Logging |

· Whether core and chip samples have been geologically and geotechnically logged to a level of detail to support appropriate Mineral Resource estimation, mining studies and metallurgical studies. · Whether logging is qualitative or quantitative in nature. Core (or costean, channel, etc) photography. · The total length and percentage of the relevant intersections logged. |

· All drill sample intervals were geologically logged by Company geologists. · Where appropriate, geological logging recorded the abundance of specific minerals, rock types and weathering using a standardised logging system that captured preliminary metallurgical domains. · All logging is qualitative, except for the systematic collection of magnetic susceptibility data which could be considered semi quantitative. · Strip logs have been generated for each drill hole to cross-check geochemical data with geological logging. · A small sample of washed RC drill material was retained in chip trays for future reference and validation of geological logging, and sample reject materials from the laboratory are stored at the Company's field office. · All drill holes have been logged and reviewed by Company technical staff. · The logging is of sufficient detail to support the current reporting of a Mineral Resource. |

Sub-sampling techniques and sample preparation |

· If core, whether cut or sawn and whether quarter, half or all core taken. · If non-core, whether riffled, tube sampled, rotary split, etc and whether sampled wet or dry. · For all sample types, the nature, quality and appropriateness of the sample preparation technique. · Quality control procedures adopted for all sub-sampling stages to maximise representivity of samples. · Measures taken to ensure that the sampling is representative of the in-situ material collected, including for instance results for field duplicate/second-half sampling. · Whether sample sizes are appropriate to the grain size of the material being sampled. |

· RC samples were cone split at the drill rig. For interpreted waste zones the 1 or 2m rig splits were later composited using a riffle splitter into 4m composite samples. · DD core was cut with a core saw and selected half core samples dispatched to Nagrom Laboratory in Perth for preliminary metallurgical test work. · The other half of the core, including the bottom-of-hole orientation line, was retained for geological reference. · The remaining DD core was quarter cored for geochemical analysis. · Since December 2018, samples were submitted to Intertek Tarkwa (SP02/SP12) for sample preparation. Samples were weighed, dried and crushed to -2mm in a Boyd crusher with an 800-1,200g rotary split, producing a nominal 1,500g split crushed sample, which was subsequently pulverised in a LM2 ring mill. Samples were pulverised to a nominal 85% passing 75µm. All the preparation equipment was flushed with barren material prior to the commencement of the job. Coarse reject material was kept in the original bag. Lab sizing analysis was undertaken on a nominal 1:25 basis. Final pulverised samples (20g) were airfreighted to Intertek in Perth for assaying. • · The pulps were submitted for analysis by Sodium peroxide fusion (Nickel crucibles) and Hydrochloric acid to dissolve the melt. Analysed by Inductively Coupled Plasma Mass Spectrometry (FP6MS) / Inductively Coupled Plasma Optical (Atomic) Emission Spectrometry (FP6/OE). The analytical suite consisted of Al, B, Ba, Be, Ca, Cs, Fe, K, Li, Mg, Mn, Nb, P, Rb, S, Si, Sn, Sr, Ta and Ti. · The vast majority of samples were drilled dry. Moisture content was logged qualitatively. All intersections of the water table were recorded in the database. · Field sample duplicates were taken to evaluate whether samples were representative and understand repeatability, with good repeatability. · Sample sizes and laboratory preparation techniques were appropriate and industry standard. |

Quality of assay data and laboratory tests |

· The nature, quality and appropriateness of the assaying and laboratory procedures used and whether the technique is considered partial or total. · For geophysical tools, spectrometers, handheld XRF instruments, etc, the parameters used in determining the analysis including instrument make and model, reading times, calibrations factors applied and their derivation, etc. · Nature of quality control procedures adopted (eg standards, blanks, duplicates, external laboratory checks) and whether acceptable levels of accuracy (ie lack of bias) and precision have been established. |

· Analysis for lithium and a suite of other elements for Phase 1 drilling was undertaken at SGS Johannesburg / Vancouver by ICP-OES after Sodium Peroxide Fusion. Detection limits for lithium (10ppm - 100,000ppm). Sodium Peroxide fusion is considered a "total" assay technique for lithium. · Review of standards and blanks from the initial submission to Johannesburg identified failures (multiple standards reporting outside control limits). A decision was made to resubmit this batch and all subsequent batches to SGS Vancouver - a laboratory considered to have more experience with this method of analysis and sample type. · Results of analyses for field sample duplicates are consistent with the style of mineralisation and considered to be representative. Internal laboratory QAQC checks are reported by the laboratory, including sizing analysis to monitor preparation and internal laboratory QA/QC. These were reviewed and retained in the company drill hole database. · 155 samples were sent to an umpire laboratory (ALS) and/assayed using equivalent techniques, with results demonstrating good repeatability. · ALL's review of QAQC suggests the SGS Vancouver and Intertek Perth laboratories performed within acceptable limits. · No geophysical methods or hand-held XRF units have been used for determination of grades in the Mineral Resource. |

Verification of sampling and assaying |

· The verification of significant intersections by either independent or alternative company personnel. · The use of twinned holes. · Documentation of primary data, data entry procedures, data verification, data storage (physical and electronic) protocols. · Discuss any adjustment to assay data. |

· Significant intersections were visually field verified by company geologists and Shaun Searle of Ashmore during the 2019 site visit. · Drill hole data was compiled and digitally captured by Company geologists in the field. Where hand-written information was recorded, all hardcopy records were kept and archived after digitising. · Phase 1 and 2 drilling programmes were captured on paper or locked excel templates and migrated to an MS Access database and then into Datashed (industry standard drill hole database management software). The Phase 3 to 5 programmes were captured using LogChief which has inbuilt data validation protocols. All analytical results were transferred digitally and loaded into the database by a Datashed consultant. · The data was audited, and any discrepancies checked by the Company personnel before being updated in the database. · Twin DD holes were drilled to verify results of the RC drilling programmes. Results indicate that there is iron contamination in the RC drilling process. · Reported drill hole intercepts were compiled by the Chief Geologist. · Adjustments to the original assay data included converting Li ppm to Li2O%. |

Location of data points |

· Accuracy and quality of surveys used to locate drill holes (collar and down-hole surveys), trenches, mine workings and other locations used in Mineral Resource estimation. · Specification of the grid system used. · Quality and adequacy of topographic control. |

· The collar locations were surveyed in WGS84 Zone 30 North using DGPS survey equipment, which is accurate to 0.11mm in both horizontal and vertical directions. All holes were surveyed by qualified surveyors. Once validated, the survey data was uploaded into Datashed. · RC drill holes were routinely down hole surveyed every 6m using a combination of EZ TRAC 1.5 (single shot) and Reflex Gyroscopic tools. · After the tenth drill hole, the survey method was changed to Reflex Gyro survey with 6m down hole data points measured during an end-of-hole survey. · All Phase 2 and 3 drill holes were surveyed initially using the Reflex Gyro tool, but later using the more efficient Reflex SPRINT tool. Phase 4 and 5 drill holes were surveyed using a Reflex SPRINT tool. · LiDAR survey Southern Mapping to produce rectified colour images and a digital terrain model (DTM) 32km2, Aircraft C206 aircraft-mounted LiDAR Riegl Q780 Camera Hasselblad H5Dc with 50mm Fixfocus lens. · Coordinate system: WGS84 UTM30N with accuracy to ±0.04. · The topographic survey and photo mosaic output from the survey is accurate to 20mm. · Locational accuracy at collar and down the drill hole is considered appropriate for resource estimation purposes. |

Data spacing and distribution |

· Data spacing for reporting of Exploration Results. · Whether the data spacing and distribution is sufficient to establish the degree of geological and grade continuity appropriate for the Mineral Resource and Ore Reserve estimation procedure(s) and classifications applied. · Whether sample compositing has been applied. |

· The RC holes were initially drilled on 100m spaced sections and 50m hole spacings orientated at 300° or 330° with dips ranging from -50° to -60°. Planned hole orientations/dips were occasionally adjusted due to pad and/or access constraints. · Hole spacing was reduced to predominantly 40m spaced sections and 40m hole spacings. Holes are generally angled perpendicular to interpreted mineralisation orientations at the Project. · Samples were composited to 1m intervals prior to estimation. |

Orientation of data in relation to geological structure |

· Whether the orientation of sampling achieves unbiased sampling of possible structures and the extent to which this is known, considering the deposit type. · If the relationship between the drilling orientation and the orientation of key mineralised structures is considered to have introduced a sampling bias, this should be assessed and reported if material. |

· The drill line and drill hole orientation are oriented as close as practicable to perpendicular to the orientation of the general mineralised orientation. · Most of the drilling intersects the mineralisation at close to 90 degrees ensuring intersections are representative of true widths. It is possible that new geological interpretations and/or infill drilling requirements may result in changes to drill orientations on future programmes. · No orientation-based sampling bias has been identified in the data. |

Sample security |

· The measures taken to ensure sample security. |

· Samples were stored on site prior to road transportation by Company personnel to the SGS preparation laboratory. · With the change of laboratory to Intertek, samples were picked up by the contractor and transported to the sample preparation facility in Tarkwa. |

Audits or reviews |

· The results of any audits or reviews of sampling techniques and data. |

· Prior to the drilling programme, a third-party Project review was completed by an independent consultant experienced with the style of mineralisation. · In addition, Shaun Searle of Ashmore reviewed drilling and sampling procedures during the 2019 site visit and found that all procedures and practices conform to industry standards. |

SOURCE: Atlantic Lithium Limited

View source version on accesswire.com:

https://www.accesswire.com/724719/Atlantic-Lithium-Limited-Announces-Significant-Potential-for-Resource-Upgrades