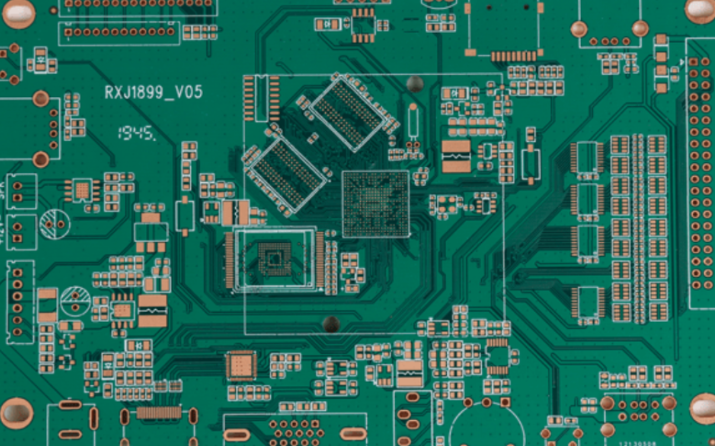

Printed circuit boards (PCBs) are the backbone of modern electronics, and most rigid printed circuit boards have a material that is called FR-4. FR-4 has emerged as an industry leader in consumer gadgets to industrial control systems because of its performance, durability, and reasonable cost. The knowledge of the FR-4, its formation, and the applications can assist designers, engineers, and decision-makers in selecting the appropriate material to use in their PCBs. In this article, the material composition, major properties, and the variety of PCB applications of FR-4 material have been presented in detail.

What Is FR-4?

FR-4 is a flame-resistant FRET which is a fiberglass-reinforced epoxy laminate commonly employed as a substrate material with rigid printed circuit boards. FR is abbreviated as flame retardant and 4 is a grade that is specified according to the industry standards. This certification guarantees that the material is of high safety and performance standards, especially in terms of fire resistance.

FR-4 has since become the default material of most standard PCB designs due to its reliability and versatility. It provides a good combination of mechanical strength, electrical insulation and thermal stability, which is applicable in a wide variety of electronic products.

Material Composition of FR-4

Its well-designed composite design gives the FR-4 its performance. It is not just one material but several layers which have a certain purpose.

Fiberglass Cloth

FR-4 is made up of woven fiberglass. This fiberglass gives the mechanical strength, rigidity, and stability in dimensions. The weaving prevents bending, cracking, and warping of the board in the manufacturing and operation process.

Epoxy Resin

Epoxy resin is impregnated to the fiberglass cloth and holds the fibers together. This resin is used as electrical insulator and gives the material resistance to fire. Chemical resistance and general durability is also improved with the help of the epoxy.

Copper Foil Lamination

Copper foil layers are laminated to the FR-4 substrate on one or both sides in order to make functional PCBs. Subsequently these copper layers are etched to create the conductive traces, pads and planes. The copper and FR-4 base have a high connection that guarantees stable electrical links.

Transportation Properties of FR-4 Material

FR-4 is popular due to the fact that it is a balanced collection of properties, which suit the requirements of the majority of electronic uses.

Flame Retardancy and Safety

FR-4 is flame-retardant and the property is one of its characteristics. It generally exceeds the UL94 V-0 flammability requirement, that is, it extinguishes itself easily, and does not drip flaming. This renders FR-4 a secure option of electronics that needs to be of fire safety standards.

Electrical Properties

FR-4 is very good in electrical insulation. Its dielectric constant (Dk) is normally between 4.2 and 4.8 that is appropriate to most of the low to medium frequency applications. The dissipation factor (Df) is also average i.e. signal loss is acceptable in normal digital and analog circuits.

Although FR-4 is not optimal in ultra-high-frequency or RF designs, it has some good results in most of the daily electronic appliances.

Mechanical Strength

FR-4 is highly mechanically strong and rigid because of the fiberglass reinforcement. It is resistant to physical stress, vibration and mechanical shock and is notably significant in industrial and automotive electronics.

Thermal Performance

The glass transition temperature (Tg) of standard FR-4 is typically 130 o C to 150 o C. FR-4 with high-Tg values (above 170 o C ) can be used where a higher thermal stability is required. Although FR-4 is not a high thermal conductivity material, it has an ability of enduring normal operating temperatures of most electronic systems.

Hydraulic and Anti-Chemical Protection

FR-4 is resistant to moisture and most commonly used chemicals. This is used to retain the electrical performance and structural integrity when operating in a humid or slightly corrosive environment.

Types and Variants of FR-4

FR-4 comes in various forms to satisfy various design needs:

Normal FR-4: General PCB designs.

High-Tg FR-4: Can be used in applications where there is high temperature and in the soldering of lead-free products.

Halogen-Free FR-4: This is created to comply with the environmental regulations of producing fewer toxic emissions.

Low-Loss FR-4: Is designed to have better signal integrity in faster digital circuits.

Such alternatives enable the designer to customize FR-4 performance in individual requirements without the need to change to completely different materials.

PCB Applications of FR-4

The broad application in PCBs is due to the versatility of FR-4 which can be used in various industries.

Consumer Electronics

FR-4 PCBs are usually used in Smartphones, laptops, televisions, and home appliances. It is cheaper and its performance is reliable thus making it ideal in mass-produced consumer equipment.

Industrial Electronics

FR-4 is used as a component of industrial control systems, automation equipment, and power monitoring equipment because of its mechanical strength and durability. These conditions are prone to vibrating, dusting, and changing temperatures on electronics and FR-4 can resist these conditions.

Automotive Electronics

FR-4 finds application in the automobile electronics like infotainment systems, engine control unit and sensor unit. FR-4 that has high Tg is particularly helpful in high-temperature application.

Medical Devices

FR-4 PCBs are widely used in many medical electronic devices as they are reliable, and they meet safety standards. FR-4 has constant electrical characteristics with diagnostic equipment, monitoring systems, and laboratory instruments.

Telecom and Networking

FR-4 is commonly used in low to medium frequency router, switch and communication module designs. In extraordinarily high-frequency RF applications, special materials might be utilized though FR-4 is usually used to support circuitry.

Benefits of FR-4 PCB Design

FR-4 has continued to be a popular PCB substrate due to several significant reasons:

Affordable relative to the high performance specialty materials.

The most popular and of uniform quality.

Highly convenient to be produced in a conventional PCB.

Excellent electrical, mechanical and thermal properties.

adhering to the safety standards.

These strengths make FR-4 almost the preferred choice of most designers except when the performance of the material must be limited by certain factors.

Limitations of FR-4

Although it is popular, FR-4 cannot be applied everywhere. Signal loss is increased at very high frequencies by its dielectric characteristics. Moreover, FR-4 is not very thermal conductive, which it is not as suitable in high-power or high-heat applications. Such materials as RF laminates, ceramic substrates, or metal-core PCBs can be of better use in such situations.

Conclusion

FR-4 has won its niche in the current PCB production. Its composite of epoxy, which is reinforced by fiberglass, provides a great solution of flame-resistance, mechanical strength, electrical insulation, and price-effectiveness. FR-4 has been used in innumerable applications in the electronics industry since it was introduced in the consumer-level electronics industry as well as industrial and automotive systems.

Although it is limited in high frequency and high power designs, there are many versions of FR-4, which give the designer numerous choices that fulfill a broad spectrum of need without compromising reliability and affordability. The knowledge of FR-4 material composition, its main characteristics, and PCB usage can help to make more appropriate design decisions and guarantee the long-term work of electronic products.